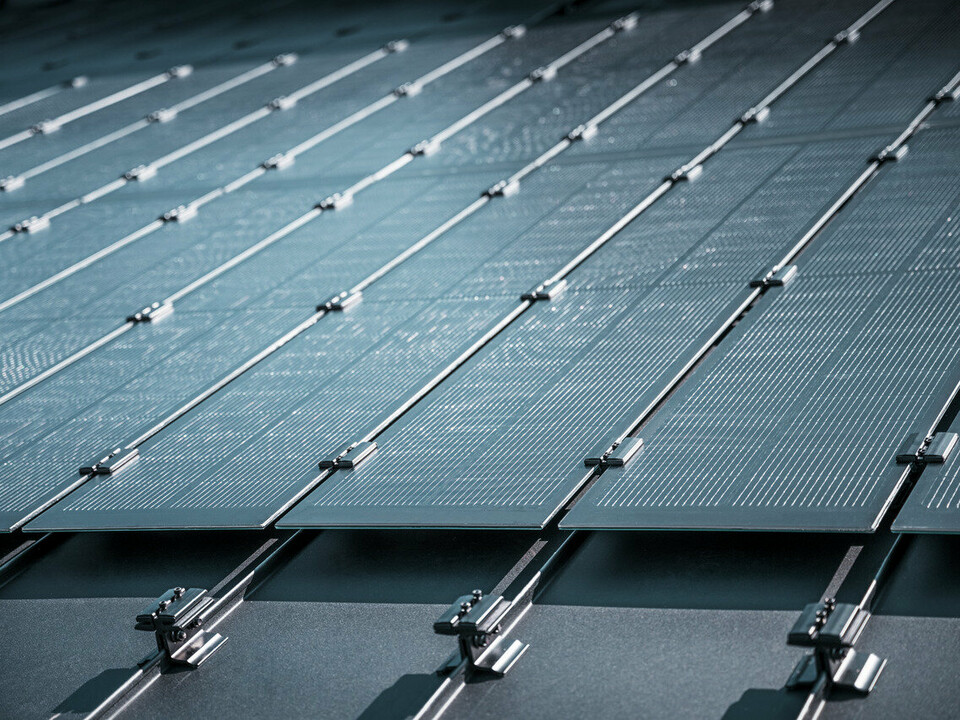

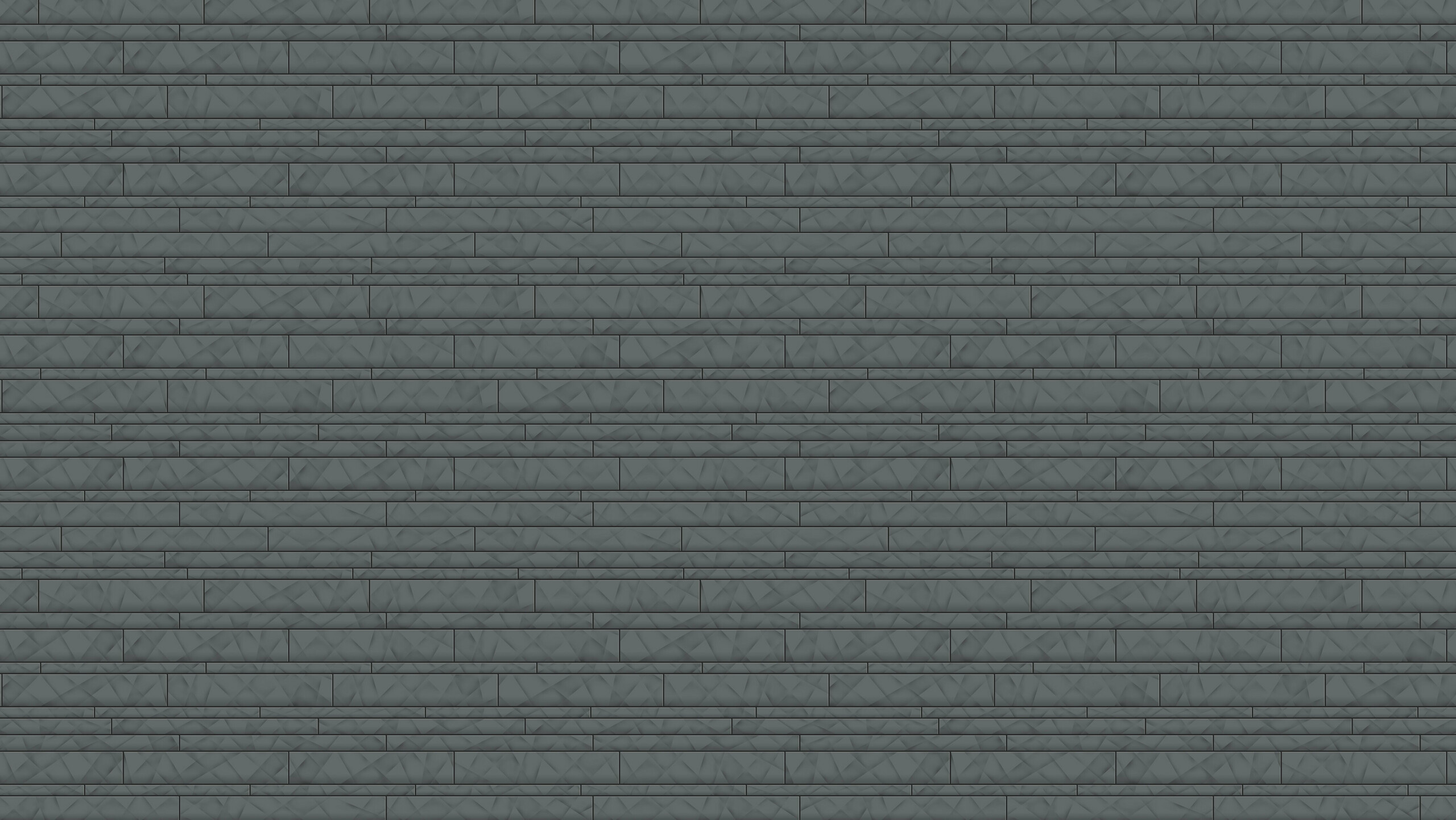

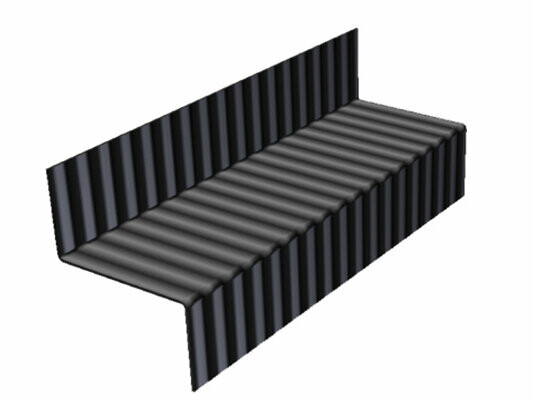

For the development of the stylish PREFA Siding.X façade panels, the sleek and classic look of the popular PREFA sidings was combined with distinctive vertical and horizontal edging. Just like the PREFA sidings, PREFA Siding.X is a high-quality façade element made of aluminium that is installed as a non-bearing, rear-ventilated façade.

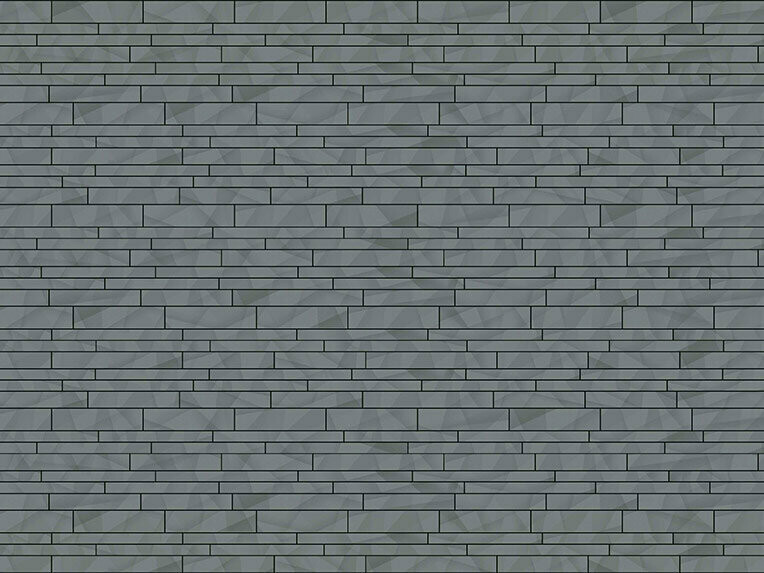

Whether it is installed vertically, horizontally or diagonally, with cross bracing or an irregular pattern, the Siding.X façade panel will lend your façade a modern and attractive surface finish. For an even greater degree of personalisation, the stylish façade can be installed with or without a shadow gap. If you want a truly unique façade with an eye-catching and high-quality finish, look no further. Siding.X is available in a range of widths and colours, which can be combined however you like. Scroll down to see a few examples of the different installation options available – or simply click here: go to the installation options.

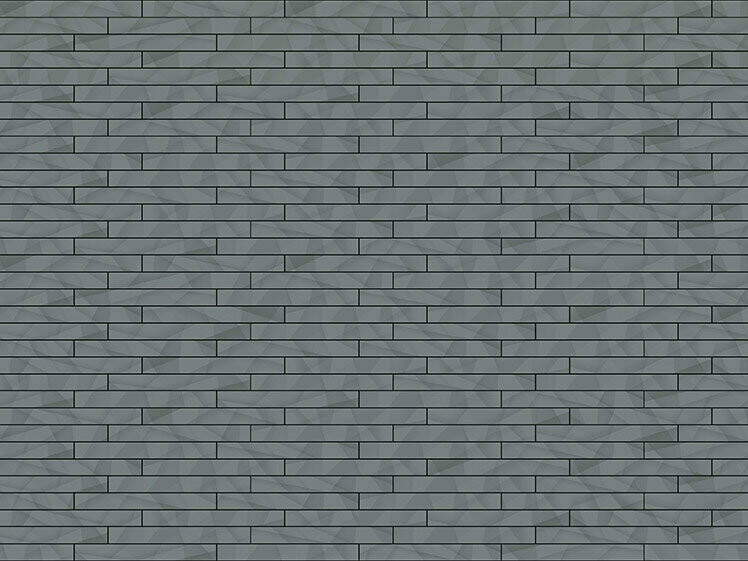

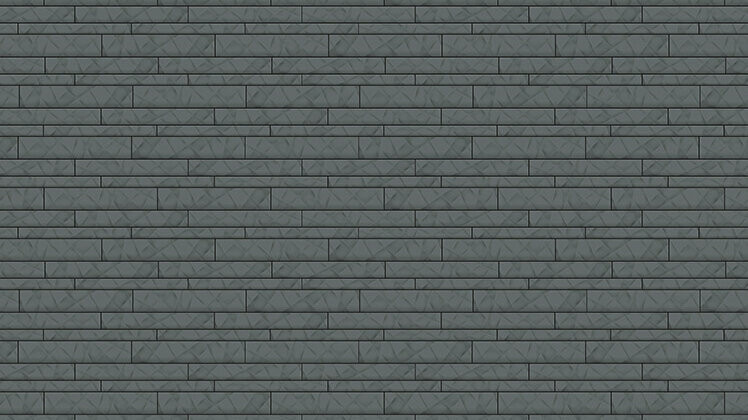

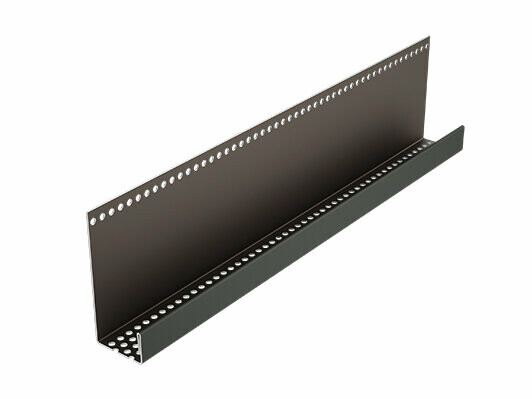

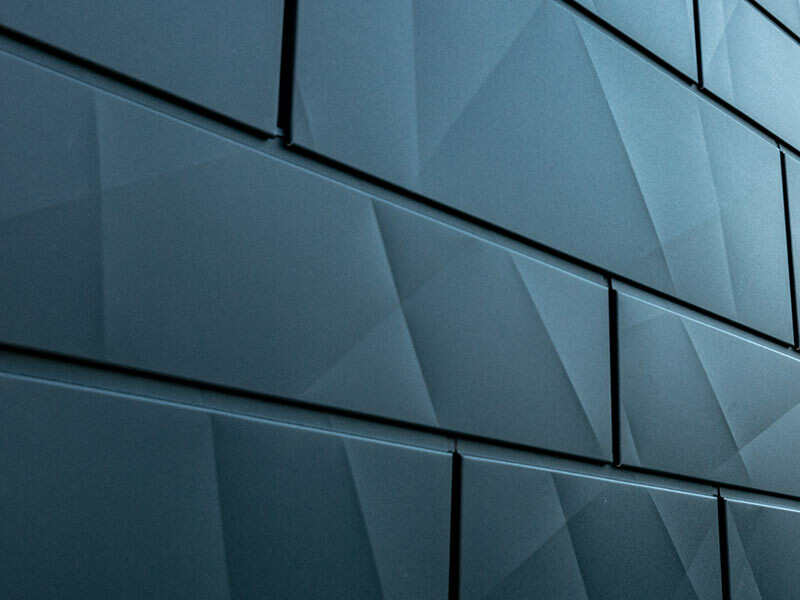

What sets the Siding.X panels apart is the edging on each individual façade element. This boosts stability while giving the façade a unique and distinctive look. Thanks to its irregular surface structure, the façade catches the light in different ways to reveal all the nuances in its colouring. Now you can enjoy a new façade with a stylish and unique appearance.

Siding.X edging in P.10 anthracite

Advantages of the PREFA Siding.X

Available in many standard colours

and lengths from 500 to 6,200 mm

Wide variety of design options

through the combination of different widths (138 mm, 200 mm, 300 mm and 400 mm), lengths and colours – discover our Siding.X installation options

Rear-ventilated façade

no condensation, no heat build-up

Fire class “A1”

non-flammable (according to EN13501-1)

Available in many standard colours

and lengths from 500 to 6,200 mm

Wide variety of design options

through the combination of different widths (138 mm, 200 mm, 300 mm and 400 mm), lengths and colours – discover our Siding.X installation options

Rear-ventilated façade

no condensation, no heat build-up

Fire class “A1”

non-flammable (according to EN13501-1)

Unique angled effect

depending on how the light hits the façade, thanks to the irregular “X” edging

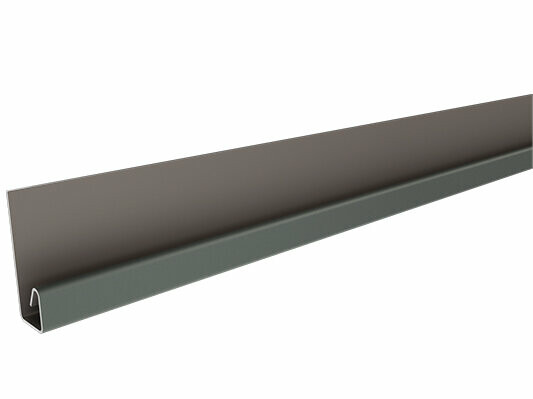

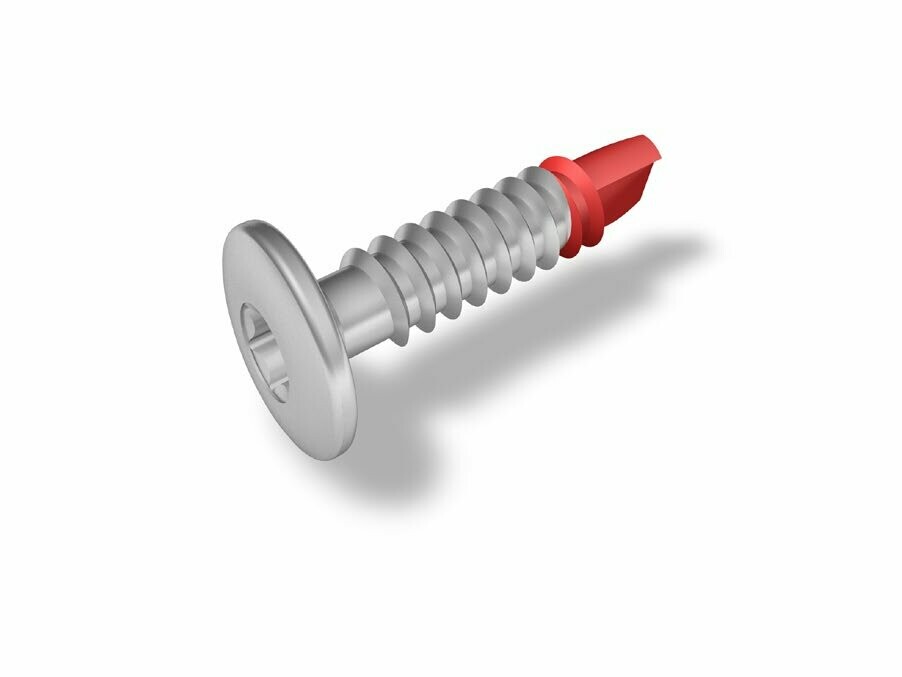

Durable construction

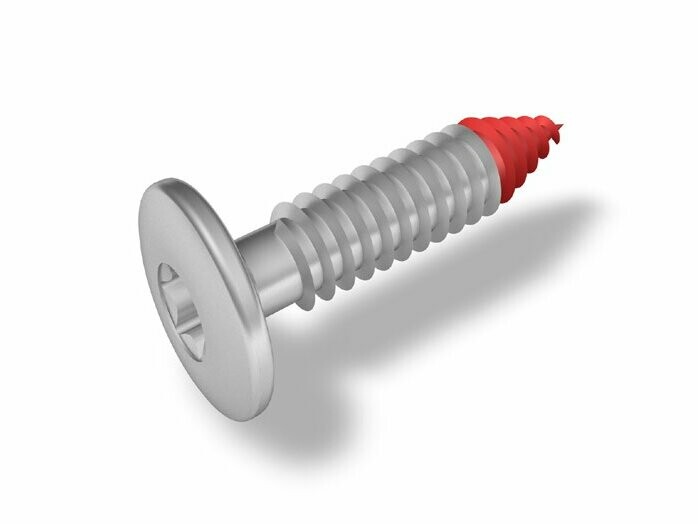

thanks to the concealed fastening mechanism that uses the tried-and-tested tongue and groove system and the PREFA storm protection clip (for widths of 300 mm and 400 mm)

Can be recycled

an unlimited number of times without any drop in quality, easy to sort into separate material types for recycling

Weather-resistant and non-rusting façade system

with a 40-year material guarantee

Unique angled effect

depending on how the light hits the façade, thanks to the irregular “X” edging

Durable construction

thanks to the concealed fastening mechanism that uses the tried-and-tested tongue and groove system and the PREFA storm protection clip (for widths of 300 mm and 400 mm)

Can be recycled

an unlimited number of times without any drop in quality, easy to sort into separate material types for recycling

Weather-resistant and non-rusting façade system

with a 40-year material guarantee

Color overview (19)

The product is available in the following colours

Color |

Code |

~ RAL |

|

|

P.10 brown |

7013 |

|

|

P.10 anthracite |

7016 |

|

|

P.10 black |

9005 |

|

|

P.10 brick red |

8004 |

|

|

P.10 oxide red |

3009 |

|

|

P.10 moss green |

6005 |

|

|

P.10 light grey |

7005 |

|

|

P.10 prefa white |

9002 |

|

|

P.10 nut brown |

8019 |

|

|

metallic silver |

9006 |

|

|

P.10 pure white |

9010 |

|

|

P.10 dark grey |

7043 |

|

|

smoke silver |

9007 |

|

|

black grey |

7022 |

|

|

P.10 prefa bronze |

7048 |

|

|

P.10 sand brown |

1019 |

|

|

P.10 stone grey |

7031 |

|

|

bronze |

7048 |

|

|

patina grey |

7042 |

Notes

- The RAL values stated are merely approximate values (~), some of which may differ vastly from the original PREFA color and, under certain circumstances, may not reflect the subjective perception of the color.

- Above all for color quality P.10, it is almost impossible to define values due to the surface structure. In addition, the PREFA Siding colours P.10 stone grey, P.10 sand brown, P.10 Prefa bronze, P.10 patina green, natural oak, patina grey, walnut and grey oak are based on natural colours made up of several different shades.

- Coils and metal sheets plain aluminium: The guarantee does not cover surface appearance alterations caused by processing and environmental influences. Follow the instructions.

- Metallic colors may vary in shade.

- To identify exact colors for complementary components please consult original samples.

Need inspiration? Take a look at some previous successful projects that feature PREFA Siding.X façade panels

PREFA Siding.X – the visual highlight on your façade. Ideal for modern new builds and creative architect-designed houses – make a mark! By putting together a unique combination of the lengths and widths available in the Siding.X façade system and picking from the wealth of colours on offer, you can tailor your façade to your exact specifications. We've put together some more tips on façade design for you here.

Be inspired by the ideas for façade design with the attractive PREFA Siding.X:

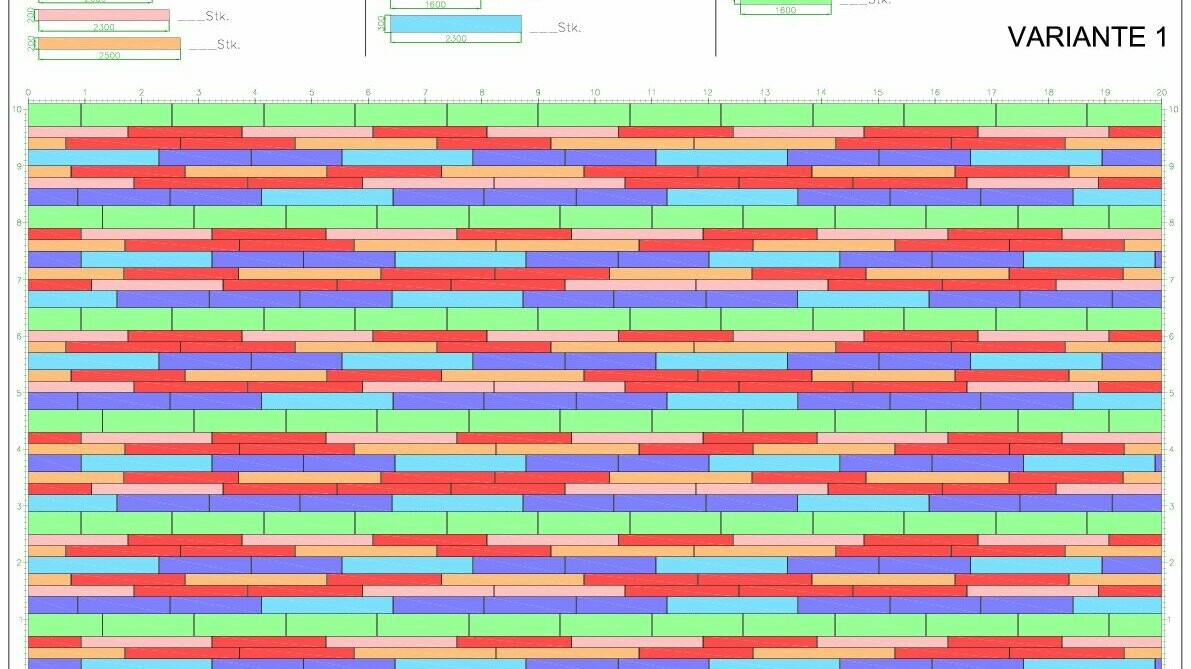

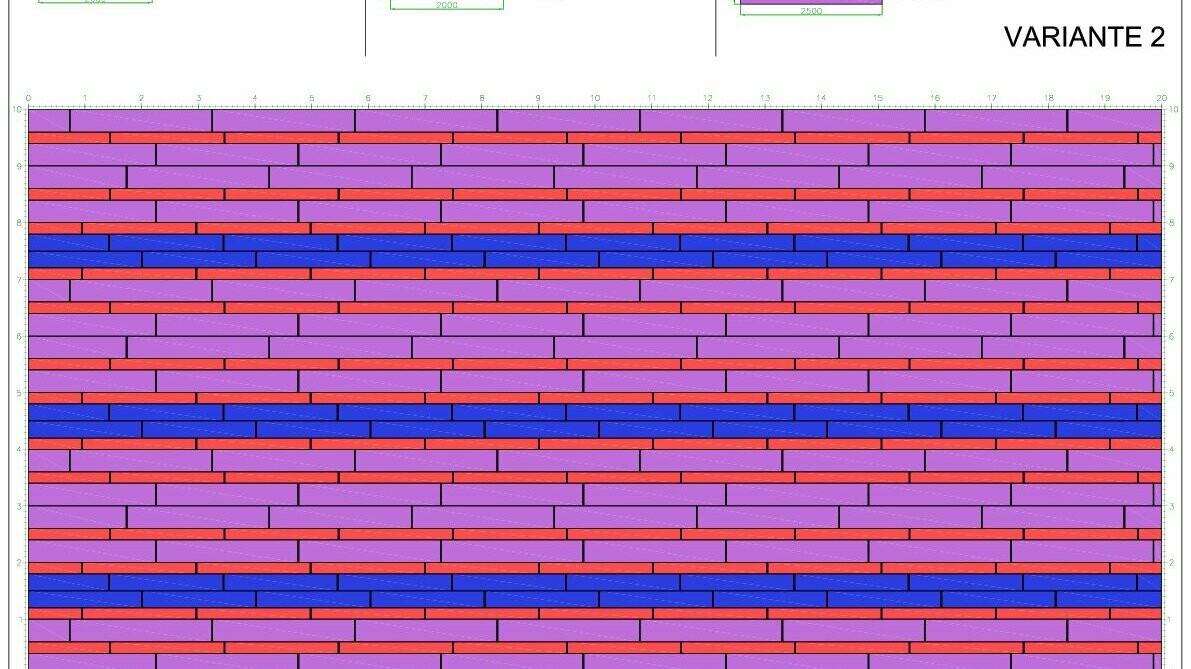

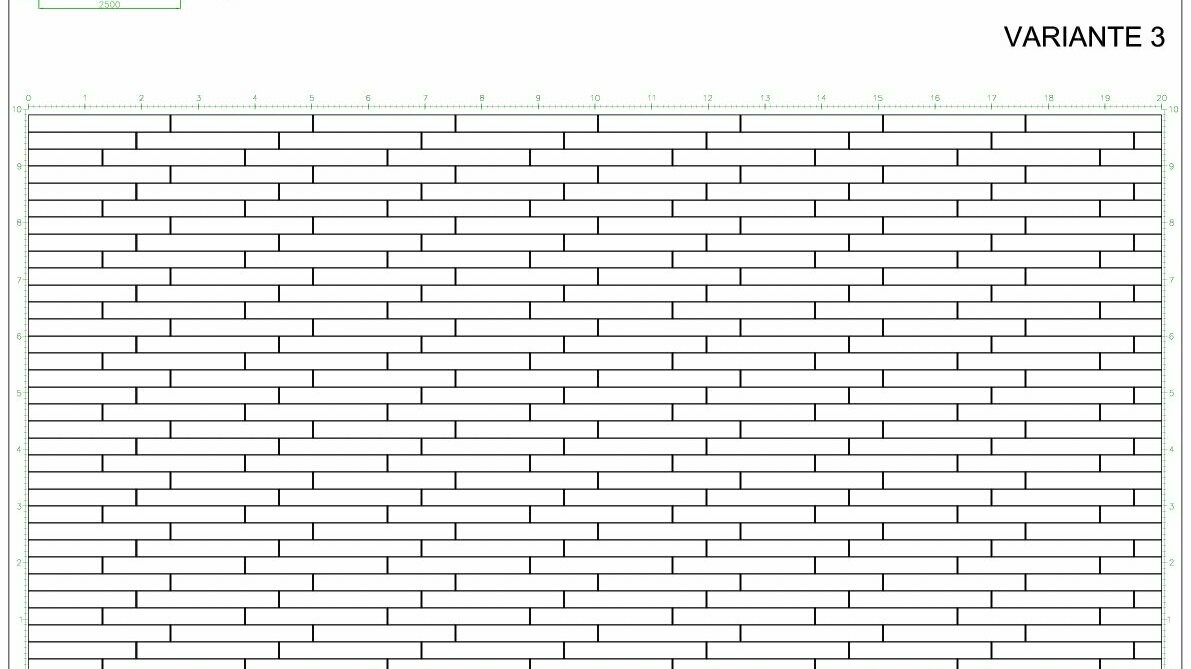

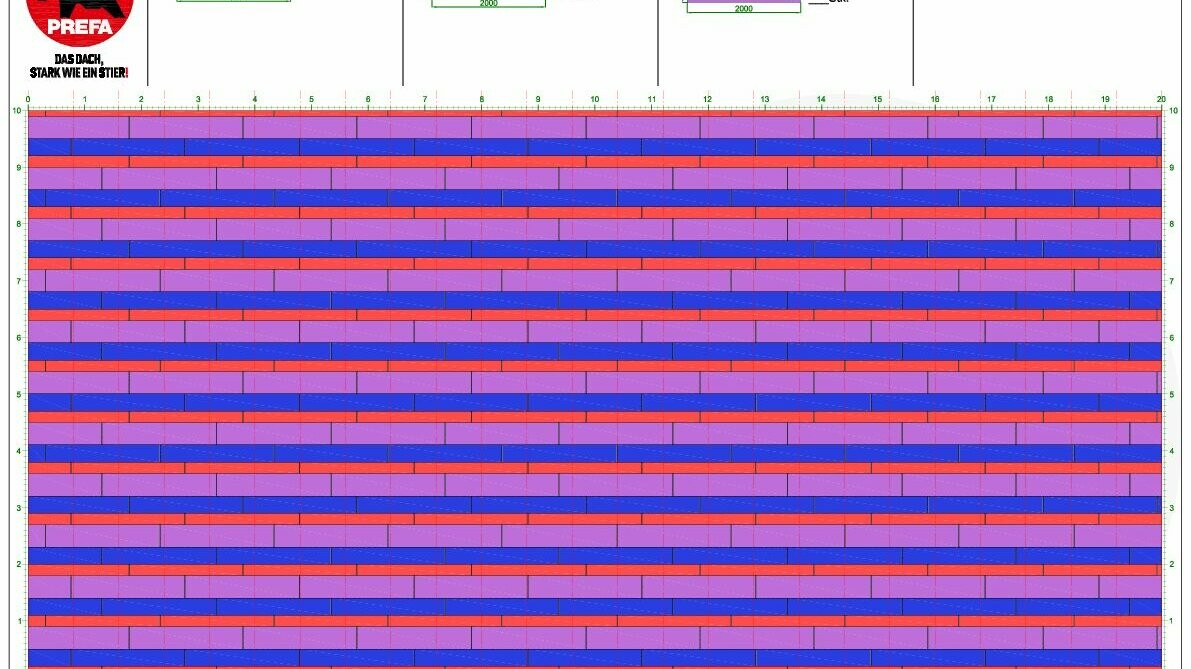

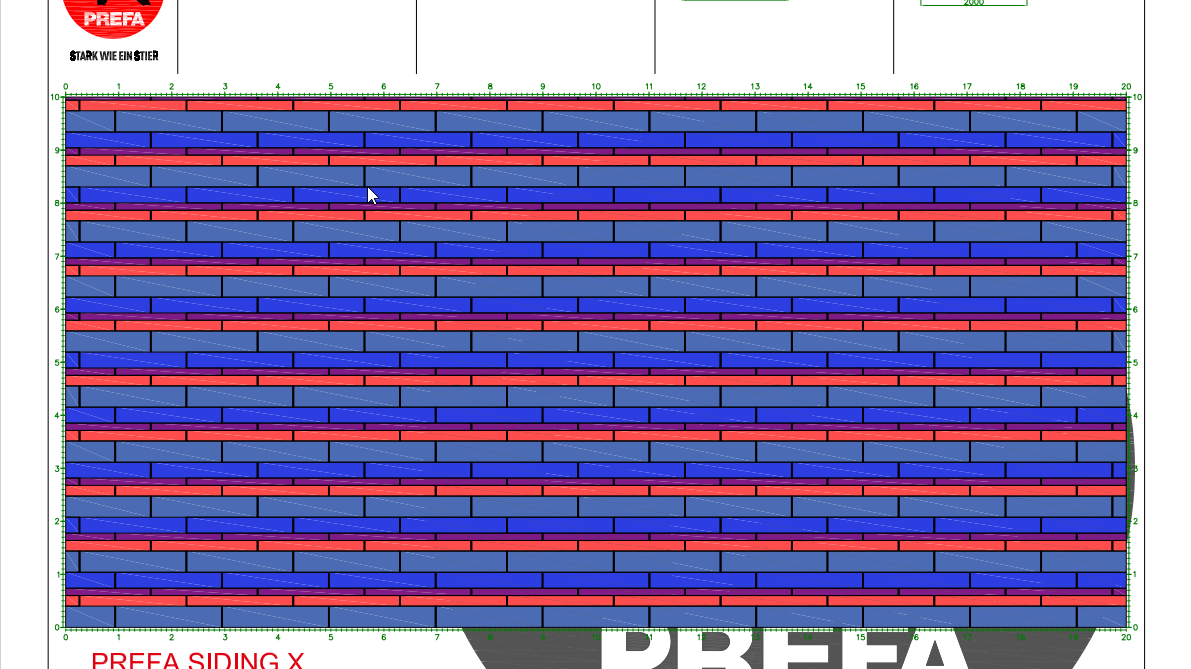

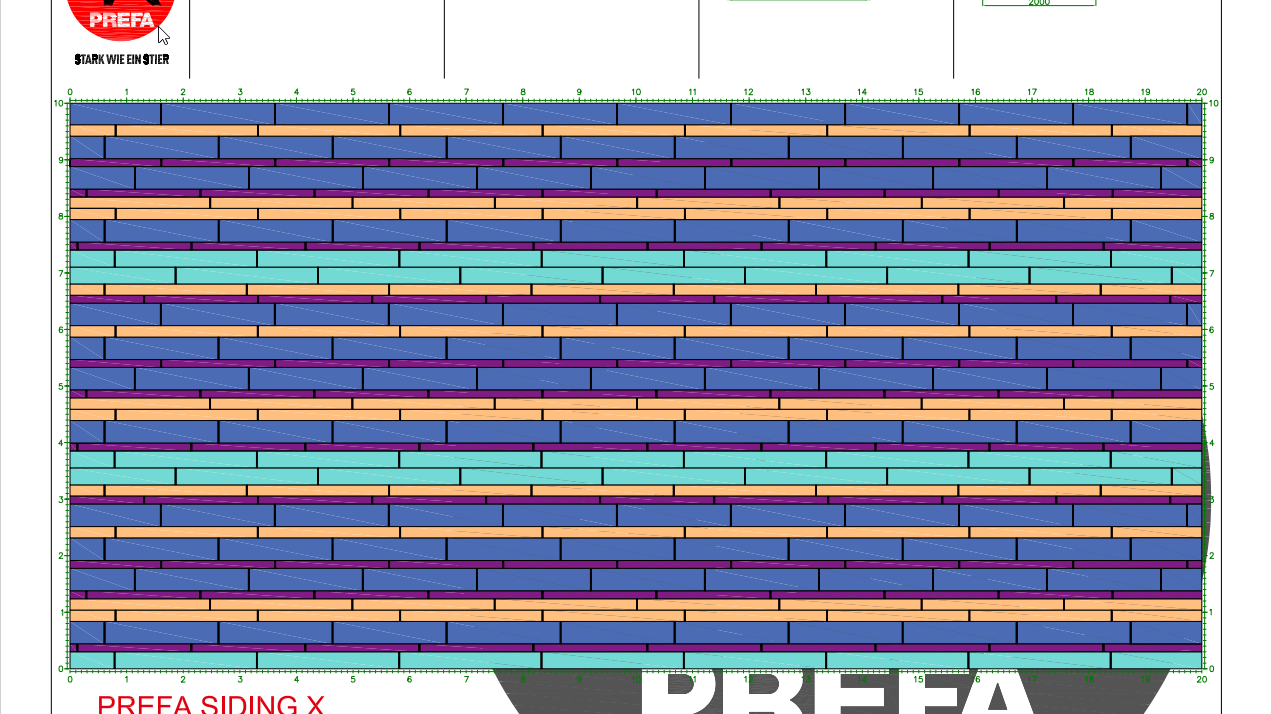

Siding.X – installation options (design options)

By combining Siding.X panels of different lengths and widths, you can create a completely individual façade for your home. We have put together a few examples for you:

Siding.X façade elements — Technical information

Coating: |

Coil coating |

|---|---|

Standard material: |

1.0 × 138 mm (material thickness/width) Special widths (from 138 to 400 mm) available on request |

Shadow gap: |

Available with or without shadow gap |

Length: |

500–2,500 mm for all widths when using the PREFA gap |

Installation: |

Horizontal, vertical and diagonal |

Substructure: |

Timber or metal substructure |

Ends: |

with or without edge downstand (11 mm) |

Weight: |

Approx. 3.30–4.30 kg/m² depending on the width |

PREFA Siding.X – Planning and installation

More product information is available for downloading here.

Note: download DWG and DXF format files by right-clicking and selecting “Save link as”.