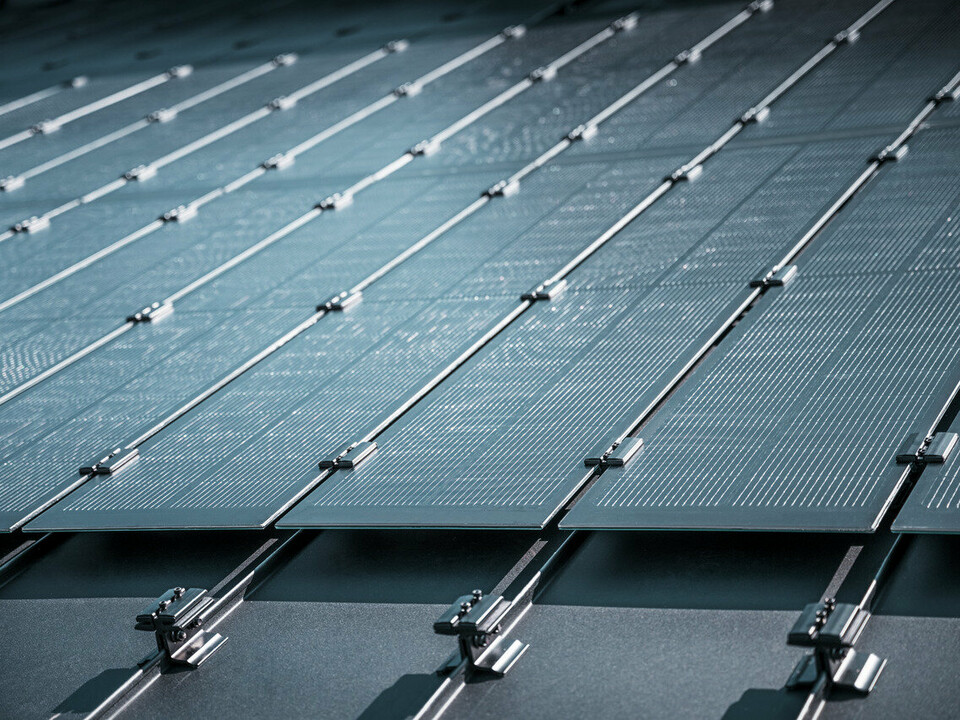

The PREFABOND aluminium composite panel is the ideal façade cladding not only for large areas, but also for small ones — it not only looks great but is also extremely durable thanks to a special combination of materials.

It is also highly resistant to corrosion and weather, and boasts high deflection stiffness and shock resistance. It also offers great design freedom with all the advantages of rainscreens.

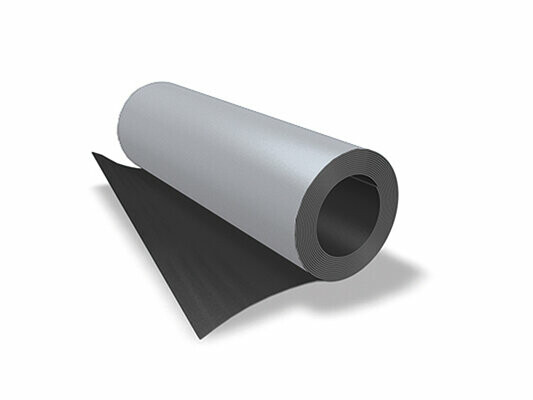

PREFABOND consists of two aluminium sheets which are fusion-bonded to both sides of an FR core (fire retardant). This connection is particularly robust due to the chemical and mechanical fastening. The aluminium composite panel thus ensures constant flatness and stability on all surfaces.

The aluminium composite panel is suitable for façade design and many construction measures:

- Ventilated façade constructions

- Cladding of balconies

- Indoors: door panels, modular partitions, floor plans

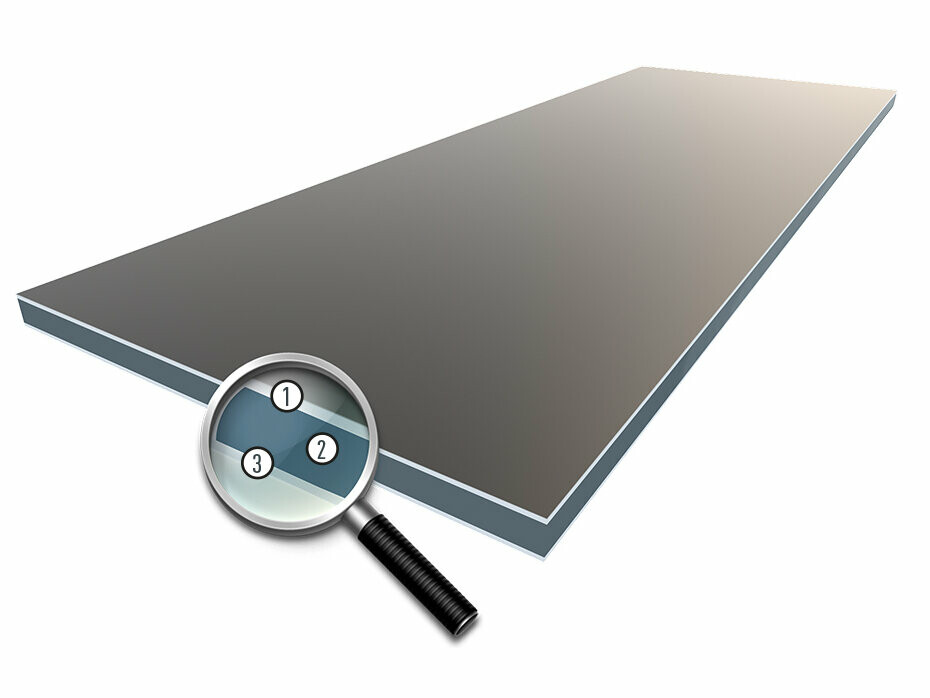

Structure of the PREFABOND aluminium composite panel

- Coil-coated aluminium (front)

- FR core (fire retardant)*

- Aluminium with protective paint (reverse)

*A2 core (non-flammable) on request

Advantages of the aluminium composite panel

Comprehensive complete system

All mounting accessories and additional items are perfectly coordinated and delivered together.

For a wide range of applications

Not only façade cladding, but also balcony cladding or indoor use is possible.

Numerous design options

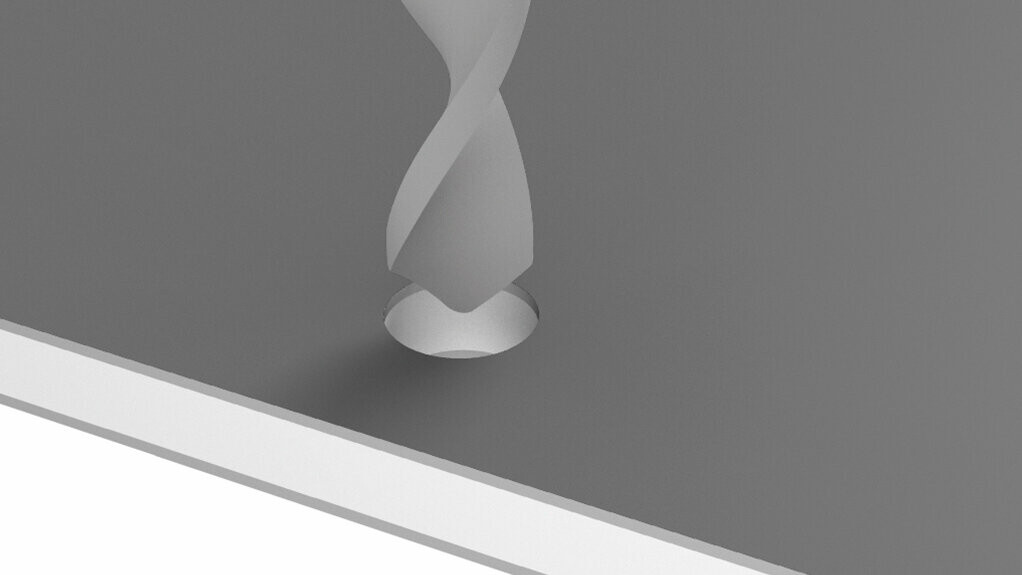

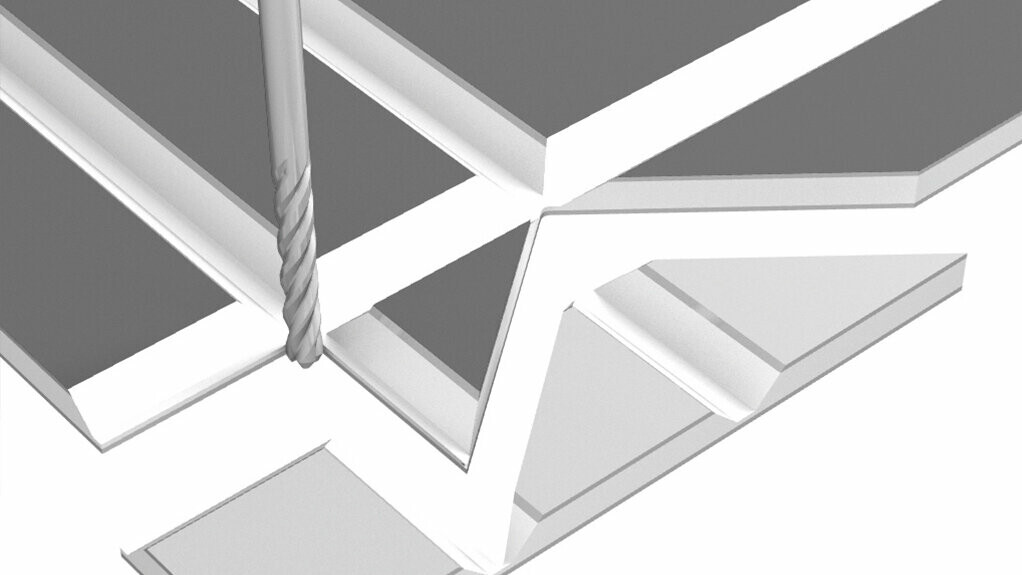

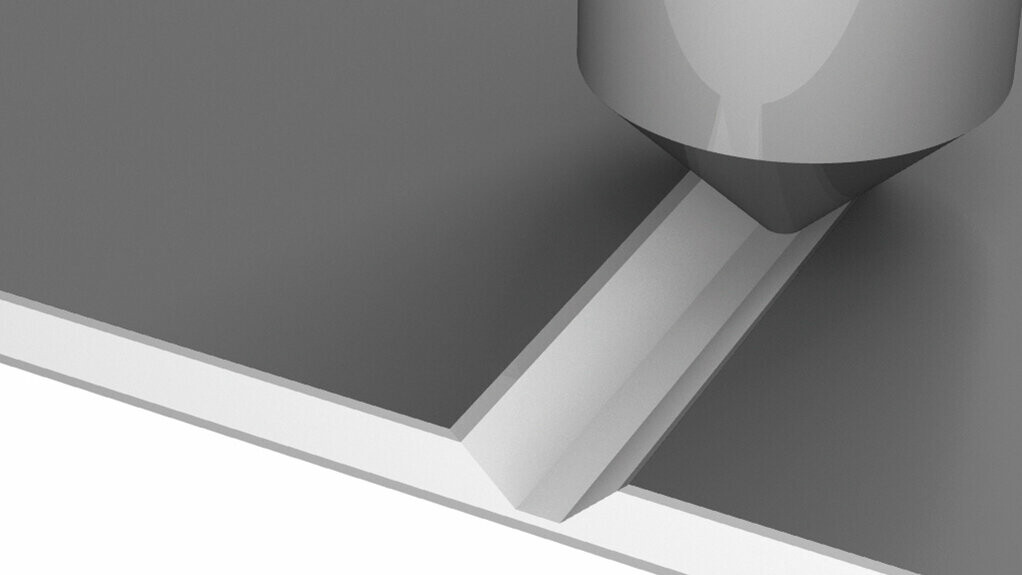

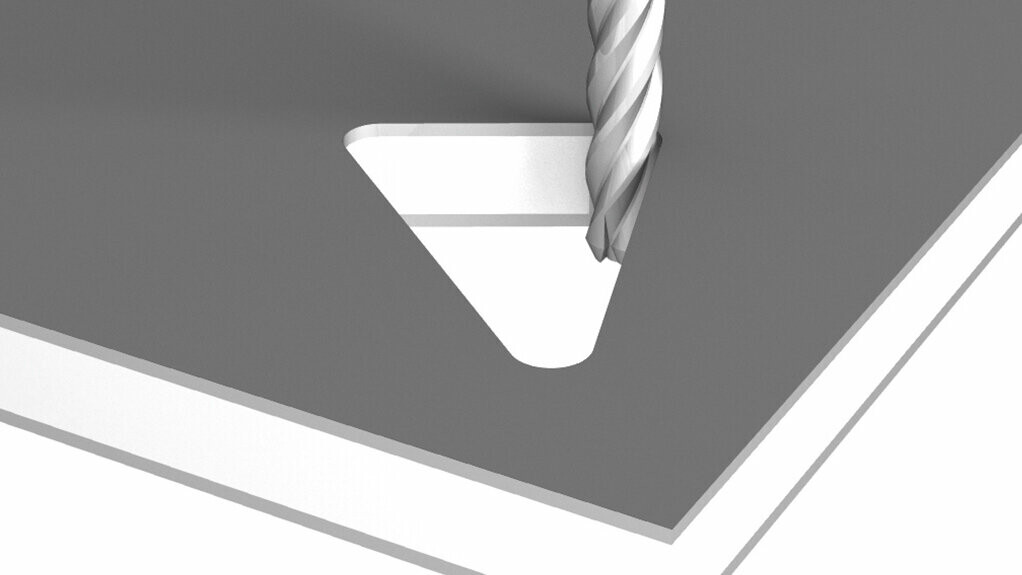

Individual façade designs through individual cutting sizes and the machining options of milling, drilling and edges (by V-groove cutting)

Comprehensive complete system

All mounting accessories and additional items are perfectly coordinated and delivered together.

For a wide range of applications

Not only façade cladding, but also balcony cladding or indoor use is possible.

Numerous design options

Individual façade designs through individual cutting sizes and the machining options of milling, drilling and edges (by V-groove cutting)

Temperature-resistant

It can be used in a temperature range of -50 °C to +80 °C.

Fire retardant

Due to its reaction to fire, the FR core complies with classification B-s1, d0 according to EN 13501-1, and an A2 core is also possible.

Low weight

of 7.6 kg/m²

Temperature-resistant

It can be used in a temperature range of -50 °C to +80 °C.

Fire retardant

Due to its reaction to fire, the FR core complies with classification B-s1, d0 according to EN 13501-1, and an A2 core is also possible.

Low weight

of 7.6 kg/m²

The numerous processing and installation options of PREFABOND : Elegant, uniform appearance

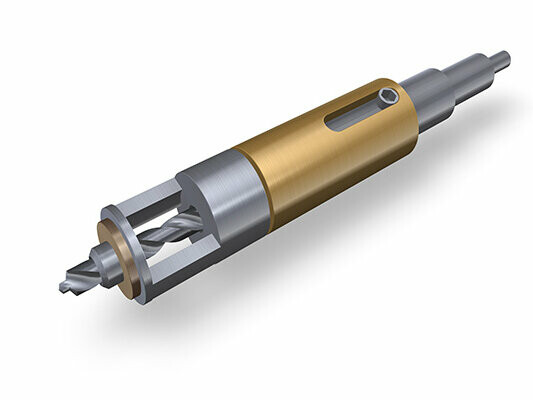

The composite panels can be screwed, riveted and glued for fastening. This results in an elegant, uniform appearance.

Milling, drilling and folding – the installation options of PREFABOND : The PREFABOND composite panel puts up with everything.

Individual design options also result from a large selection of colours and individual cutting sizes. The composite panels are ideal wherever small areas are required to make a big impression.

The standard panel has a raw format of 4,010 × 1,535 mm (usable format: 4,000 × 1,525 mm). Different formats can be cut from this depending on requirements. Versatile machining options such as milling, drilling and folding are also possible. All this with a minimum weight of just 7.6 kg/m².

Panel bending of PREFABOND aluminium composite panels is also possible. Thus, for example, rounded corners can be manufactured. The panels are bent in a convex or concave manner or with a straight off-cut.

Rounded external corners with PREFA aluminium composite panels in bronze and black grey

Fire retardant

Only the best quality for the toughest of requirements. For this reason, the PREFABOND aluminium composite panel is already equipped with an FR core (fire retardant) as standard. Due to its reaction to fire, the FR core complies with classification B-s1, d0 according to EN 13501-1. The PREFABOND composite panel is also available on request with an A2 core (non-combustible), which corresponds to the classification A2-s1, d0 according to EN 13501-1 due to its reaction to fire.

Temperature resistance

The PREFABOND aluminium composite panel is also ideally suited for extreme conditions. It can be used in a temperature range of -50 °C to +80 °C.

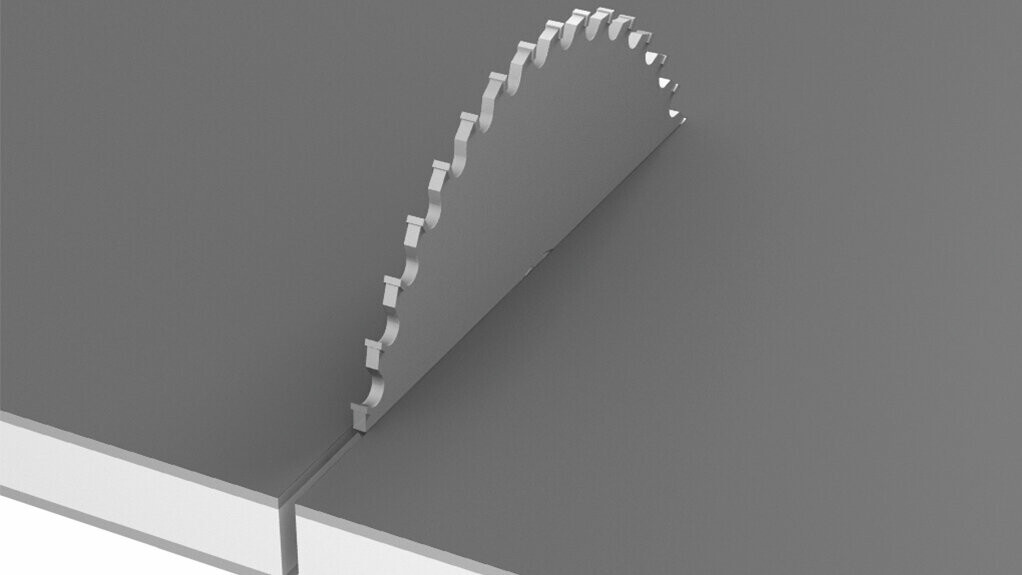

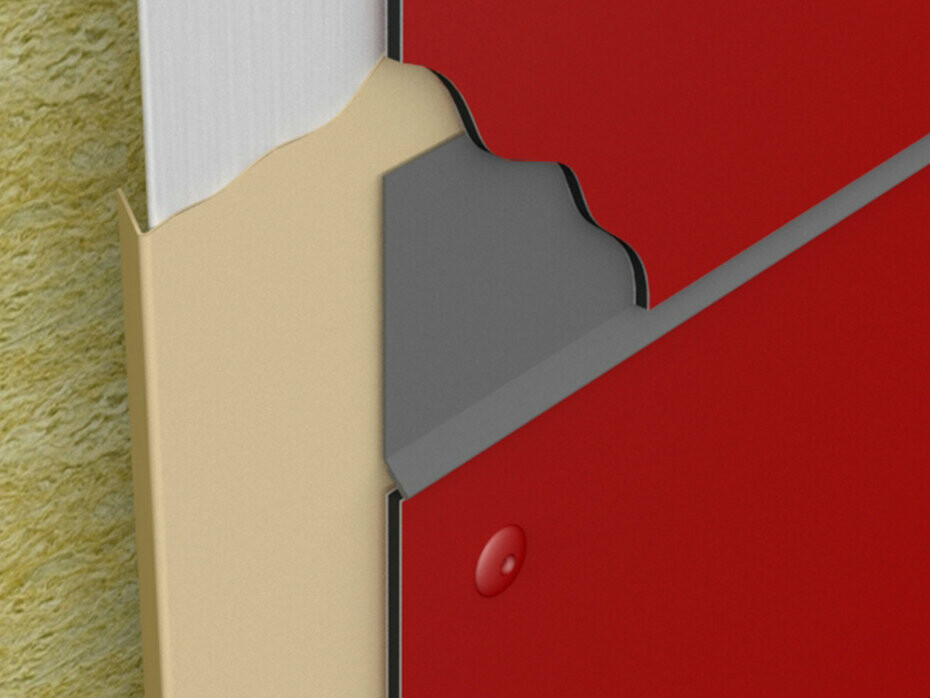

Joint backing strip

The horizontal or vertical joint backing strip not only protects the substructure but can also be used as a visual highlight between the panels. Either you adapt the colour of the joint backing strip to the panel colour and leave it deliberately discreet, or it should stand out by consciously using a lighter or darker colour than the façade colour.

Colour range of the aluminium composite panel

The aluminium composite panel is available in many colours:

- Special colours and gloss levels as desired are available on request.

- All RAL colours are available on request (subject to feasibility).

- Standard colours from 6 m²

Color overview (15)

The following table contains the standard PREFABOND colours:

Color |

Code |

similar to RAL colour |

|

|

P.10 anthracite |

7016 |

|

|

P.10 black |

9005 |

|

|

P.10 prefa white |

9002 |

|

|

P.10 nut brown |

8019 |

|

|

metallic silver |

9006 |

|

|

pure white |

9010 |

|

|

P.10 pure white |

9010 |

|

|

P.10 dark grey |

7043 |

|

|

smoke silver |

9007 |

|

|

black grey |

7022 |

|

|

brushed aluminium |

|

|

|

P.10 prefa bronze |

7048 |

|

|

matt anthracite (own colour) |

7016 |

|

|

bronze |

7048 |

|

|

patina grey |

7042 |

Notes

- The RAL values stated are merely approximate values (~), some of which may differ vastly from the original PREFA color and, under certain circumstances, may not reflect the subjective perception of the color.

- Above all for color quality P.10, it is almost impossible to define values due to the surface structure. In addition, the PREFA Siding colours P.10 stone grey, P.10 sand brown, P.10 Prefa bronze, P.10 patina green, natural oak, patina grey, walnut and grey oak are based on natural colours made up of several different shades.

- Coils and metal sheets plain aluminium: The guarantee does not cover surface appearance alterations caused by processing and environmental influences. Follow the instructions.

- Metallic colors may vary in shade.

- To identify exact colors for complementary components please consult original samples.

Get inspired by the projects already implemented with aluminium composite panels

The PREFABOND aluminium composite panel offers almost unlimited design options. The durable material is used in new buildings as well as in renovations and also ensures a special look in interior design. The PREFABOND aluminium composite panel can be screwed onto wooden substructures, riveted onto aluminium substructures and glued in both cases. It thus ensures an elegant, uniform appearance on both large and small surfaces or deliberately demonstrates architectural ingenuity. The wide range of colours, shapes and gloss levels creates a unique look.

Modern cladding for your balcony

PREFABOND aluminium composite panels are also suitable for balcony cladding: The high-quality surface coating protects the panels against weather influences for decades and is also extremely colourfast and dirt-resistant. Panels coated on both sides are available on request and subject to feasibility.

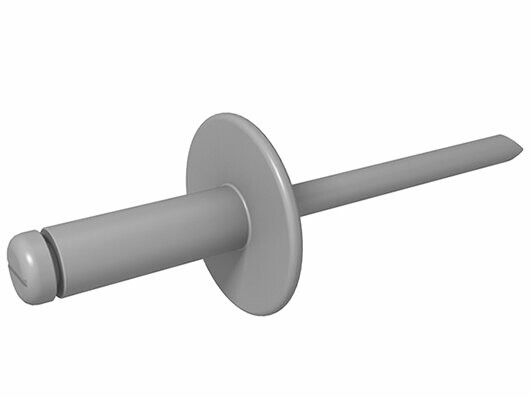

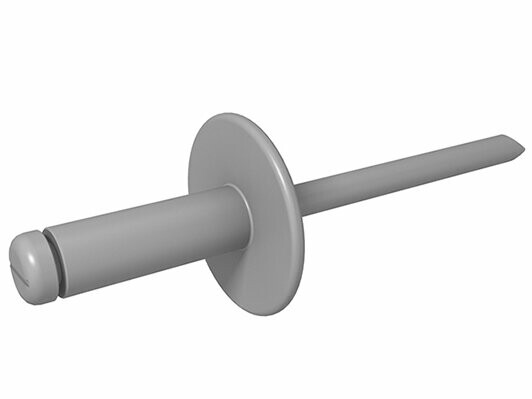

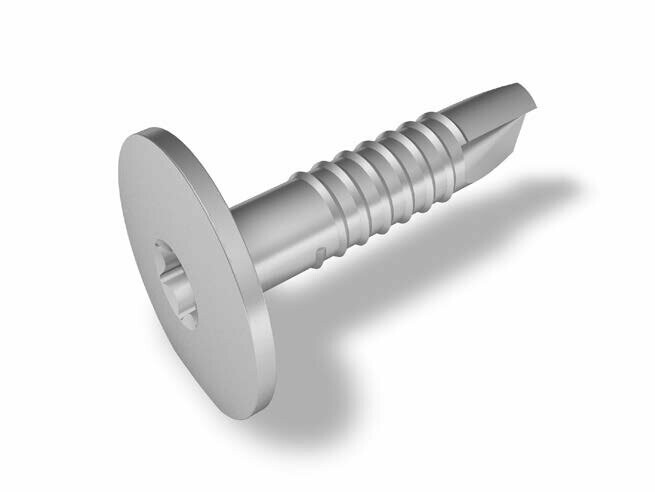

With the stainless steel balcony rivet with the dimensions 5 × 14 mm and a head diameter of 15 mm, PREFABOND as well as serrated profile and ripple profile panels are fastened in an excellent manner to balcony and parapet cladding. In the system, the balcony rivet is tested for the increased requirements with regard to fall-through protection. This is proven by pendulum impact tests in accordance with the requirements of the ETB Directive (components that protect against falls) and EN 12600:2002-11 in cooperation with an external testing institute.

Technical information about aluminium composite panels

Coating on front: |

DURAGLOSS 5000 is an exclusive Arconic paint with a recently developed coating made of high-quality polymer resin, and is available in four colours. The gloss level is between 3 and 80%. |

|---|---|

Core: |

FR core (fire retardant) |

Coating on reverse: |

Protective paint, suitable for adhesion, offers excellent corrosion protection. The coating direction is indicated by arrows on the back. This enables you to correctly align the tiles on the façade. |

Standard dimensions: |

thickness: 4 mm; width: 1,500 mm; length: 4,010 mm

|

Dimensions available on request (from 500 m²): |

thickness: 4 mm; width: 1,000/1,250/1,500/1,750/2,000 mm; length: between 2,000 and 6,000 mm |

Weight of the aluminium composite panel (FR): |

4 mm = 7.5 kg/m²

|

Fire protection rating (aluminium composite panels FR): |

Austria (EN 13501) – B-s1-d0

|

Temperature resistance: |

between –50 °C and +80 °C |

Linear thermal expansion: |

A = 0.024 mm/m/°C (based on the aluminium cover plate) |

Change in length at a temperature difference of 60 °C: |

1.4 mm per metre |

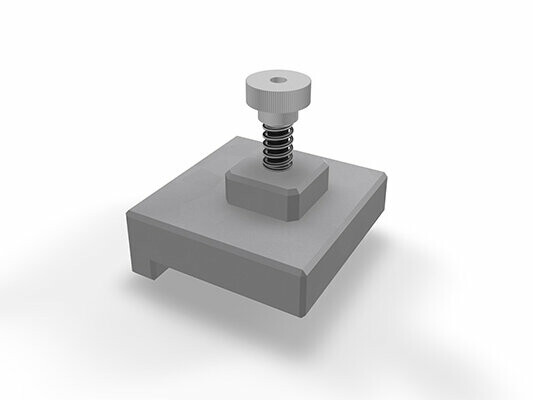

Fastening: |

on timber supporting substrate: screwed down or glued |

Aluminium composite panel — Planning and installation

You will find specification documents as well as details about PREFABOND aluminium composite panels for download here.

Details

Aluminium composite panels – Accessories

For a complete, detailed list of accessory products, see our price list (only for processors).